Description

Silicone systems are ready to use, that cures as resilient silicone rubber at room temperature. These are versatile products, which finds immense use in all kinds of industries, offering exceptional properties. It can be used as a ADHESIVE, SEALANT & F.I.P. GASKETING.

SALIENT FEATURES:

Good thermal stability (-50°C to +250°C)

Excellent mechanical properties

Good dielectric properties

Good weather ability & UV resistance

High Elasticity

Applications:

Automotive Industries: Used as a (F.I.P. Form- in Place) Gasketing Sealant for engine assembly such as oil pan, Transmission covers, water pump mounting etc., and also for body building applications.

Aircraft Industries: Used as gaskets, sealing, ducting, vibration dampers.

Construction Industries: Used for glass glazing, window perimeter joints, wash basin / bathtub sealing, A/C duct sealing etc.

RUBBER BASED-NON CURING (BUTYL TAPES):

Non-Curing rubber based Butyl mastic putty & tapes are highly tacky compounds possessing excellent peel strength & goods adhesion to metal & non-metal with good weathering properties.

Salient Features:

High elongation

Posses excellent peel strength

Highly tacky compound

Effectively seals and dampens vibration

Excellent addition on most of the substrates

Applications:

Sealing on air conditioner compressor and condenser to prevent entry of water and moisture.

Insulating compounds in bus bar joints, electrical connections.

Door trim sealing for preventing ingress of moisture and vibration.

Sound dampening pads for noise reduction in Automobiles, Air conditioners and gensets.

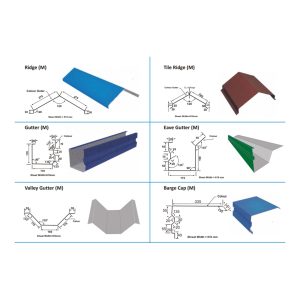

Sealing joints encountered in pre engineered metal building fabrications such as vents, gutters, roof jacks, window tins door fins etc.

POLYURETHANE:

Polyurethanes (one part & two part systems) are highly versatile compounds, which finds enormous use in engineering CASE (Cooling, Adhesive, Sealant, Elastomer) applications. The versatility of polyurethane means that it can be formulated in to a soft elastomer to a hard solid. Anabond’s polyurethane are offered in a wide range of viscosity, curing time, pot life, flexibility, hardness and strength.

One part systems:

Anabond 702 / 722 is a single compound silylated polyurethane sealant suitable for automobile and construction applications. It has better paintability than silicone sealants.

Anabond 745 is a single part room temperature curing lamination adhesive to bond aluminum to flexible polyurethane foam.

Acrylic Sealant

Anabond 777 acrylic sealant is a single component whe cured produces a flexible seal with non-yellowing properties, while curing forms a tough and resilient bond in civil engineering applications.

SALIENT FEATURES:

One component, easy to apply

Good adhesion on building materials

Durable and ageing resistance

High flexibility

Paintable

Applications:

Joint sealing between windows and door frames.

Expansion joints between concrete building component of smaller size.

Water proof sealing of air conditioning room, clean room, cold storage, laboratory etc.