Description

Metal -faced polyurethane sandwich panels are the system of choice today for large industrial buildings, refrigerated ware houses, office blocks, exhibition halls, fair pavilions, schools and sports halls.

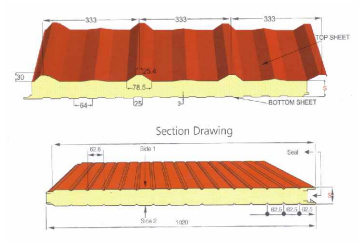

The aluminium or steel facings themselves are surface coated and can be manufactured with profiles of various

depths leading to a higher load bearing.

Polyurethane sandwich panels come complete with specially formed tongue – and – groove joints ensuring a

perfect fit and maximum integrity. Assembly is fast, easy and cost effective.

The resultant sandwich panel has a load-dearing capability many times greater than that achieved by adding together the load-bearing capacities of the individual layers. As a result, these thin, relatively lightweight sandwich panels can safely bridgewide spans.

Puf insulated sandwich panels for roof and wall :

These panels functions well as a roof or wall panel when used in conjunction with pre-engineered buildings or

conventional steel framing systems. The product features an overlapping major rib at the panel sidelap, this sandwich panel is filled with CFC free polyurethane in the core achieving Good R- Values and consists of exterior and interior facings of relatively thin metal sheet profiled.

Panel strength will be more because of double sheet with corrugated profiles with core thickness varies from – 30 – 120 mm thickness. Purlin spacings will be upto 5 m so that steel structure cost in purlin will be saved.

Specifications :

Panel thickness available: 30mm, 40 mm, 50 mm, 60 mm, 80 mm, 100 mm, 120 mm

Panel width available: 1060 mm / 1090 mm

Panel length available: 2000 mm – 12000 mm

Average density: 40 + 2kg/m

Thermal conductivity: 0.024-0.03 W/m

Temperature range: -40 + 80 C

Fee from CFC: CFC Free

Type of foam: B1, B2, B3, & PIR

Heat Transfer co-efficient: = 0.022W / M2*K

Pressure: 0.10 Mpa

Cubic Area Change: = 1% (-30 C – 100 C / 96h)

Panel Sheets specifications :

Polyester primer: 5 micron

Non-toxic food-graded STANDARD Polyester finish paint RAL 9010 colour: 20 micron

Back – coat: 5 micron

Resistance to Saline mist: > 500 h (ECCA TB)

resistance to moisture: 1000 h (ASTM D 2247)